Metal Mesh / Wire Mesh

JUNEN metal mesh / metal wire has been in the metal mesh industry for over 30 years and our reputation in the industry is well recognized, and all our product meet to the related international standard & regulation.

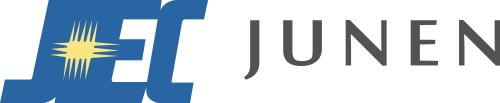

We are the expanded metal / perforated mesh / wire conveyor belt supplier of versatile which are all made from a high-quality metal sheet. Our expanded metal sheet is available in many sizes and different material types such as galvanized, stainless steel, iron, aluminum, etc. The waste material won't be generated during the expansion of the producing process, saving a lot of waste material costs and cost-effective. Moreover, this metal sheet is forming diamond-shaped openings in the sheet that allows for passage of light, air, heat and sound. The strands and bonds of diamonds in the sheet is lighter in weight and stronger in structure than the original sheet.

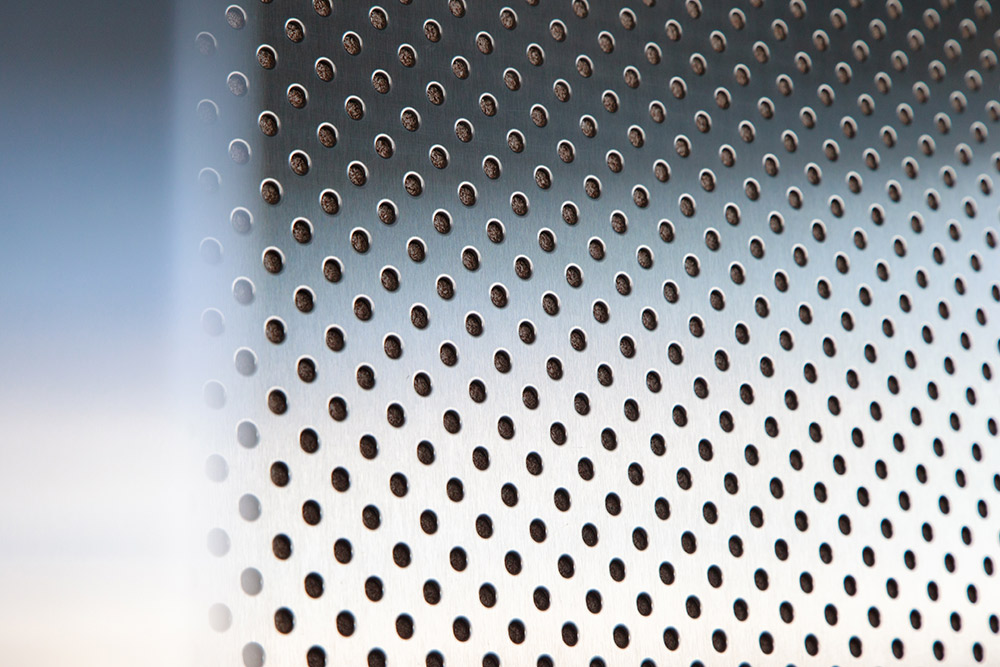

Moreover, we have also manufacture perforated metal, it is one of the most versatile and popular metal products on the market at present. The perforated metal can range from light to heavy gauge thickness. JUNEN is using our own high speed perforated mesh machine to punch into different shapes such as round, square, rectangular or quincunx. It can have versatile opening, in the way that it can have very small or large aesthetically appealing openings. This makes perforated sheet metal ideal for many architectural metal and decorative metal uses Perforated metal perforated mesh also adds structural integrity to stairwells, sidewalks or mezzanine structures, while providing an aesthetic appearance that complements multiple styles. JUNEN is the one who manufacture metal mesh and metal wire who knows the best way to make the most excellent mesh products.

Various Type of JUNEN Metal Mesh/ Wire Mesh

- Expanded Metal

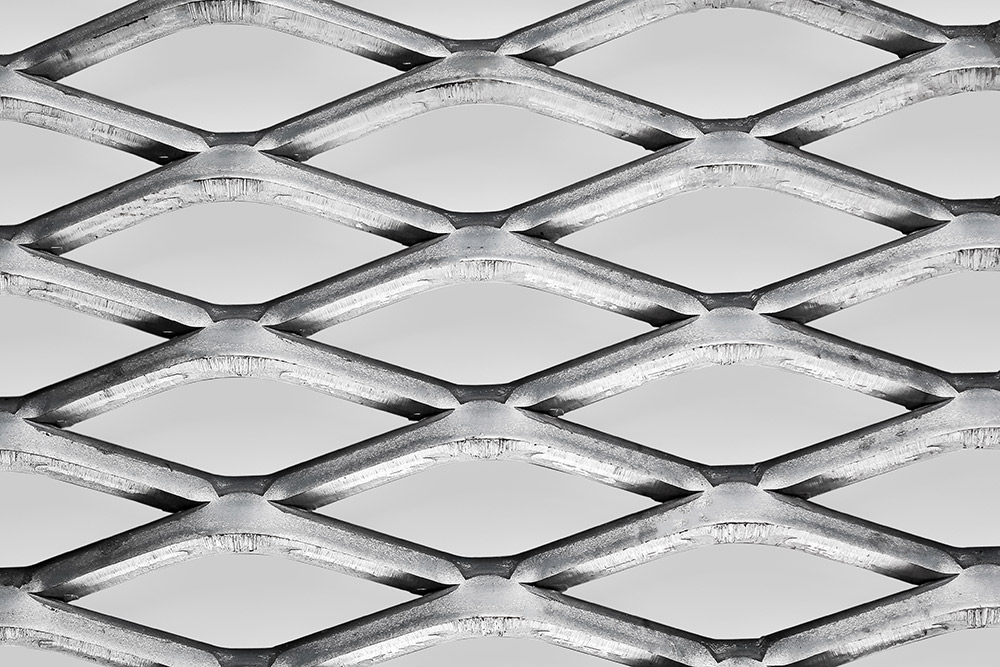

- Wire Convyor Belt

- Perforated Mesh

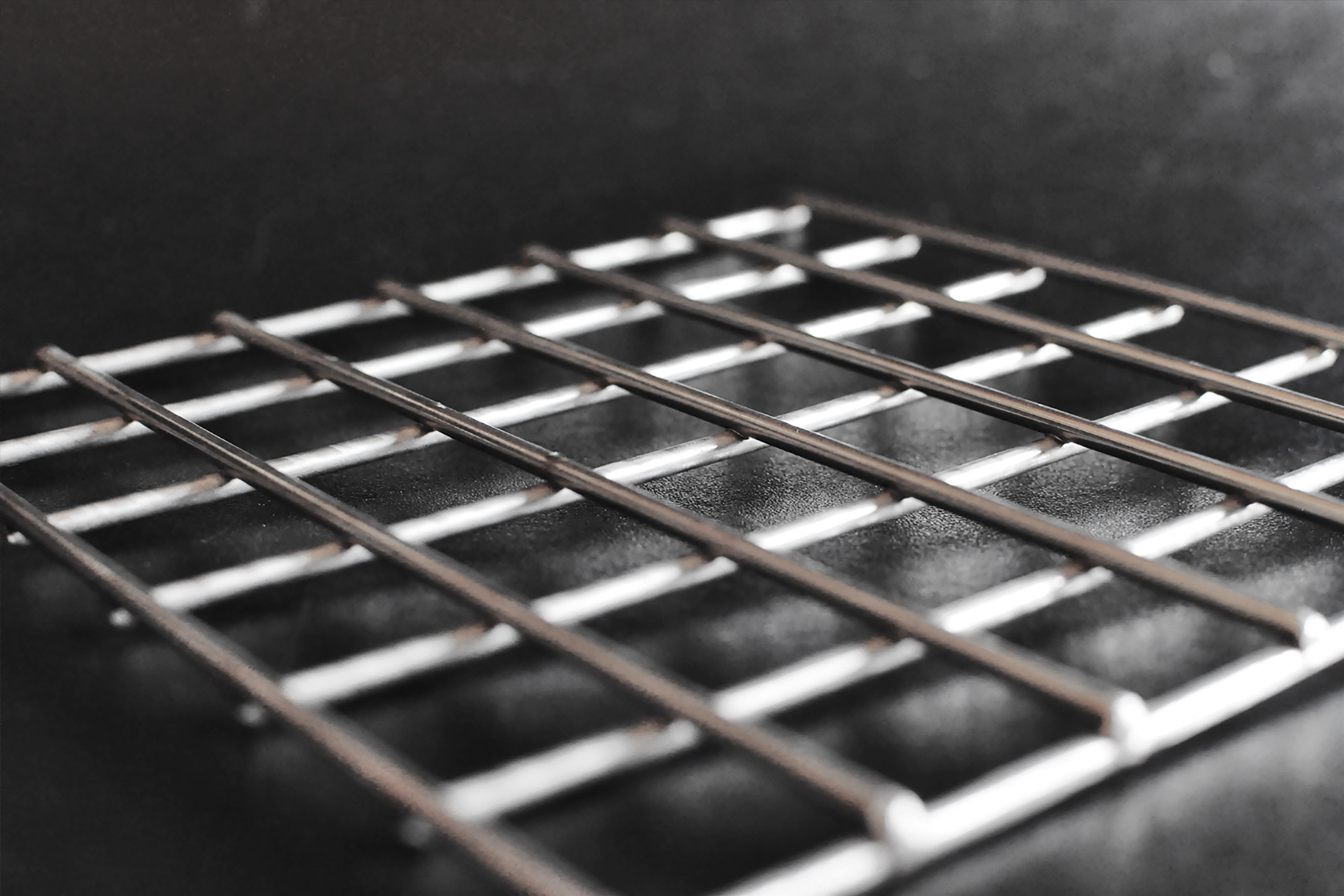

- Mesh Grid

- Chain Link Fence

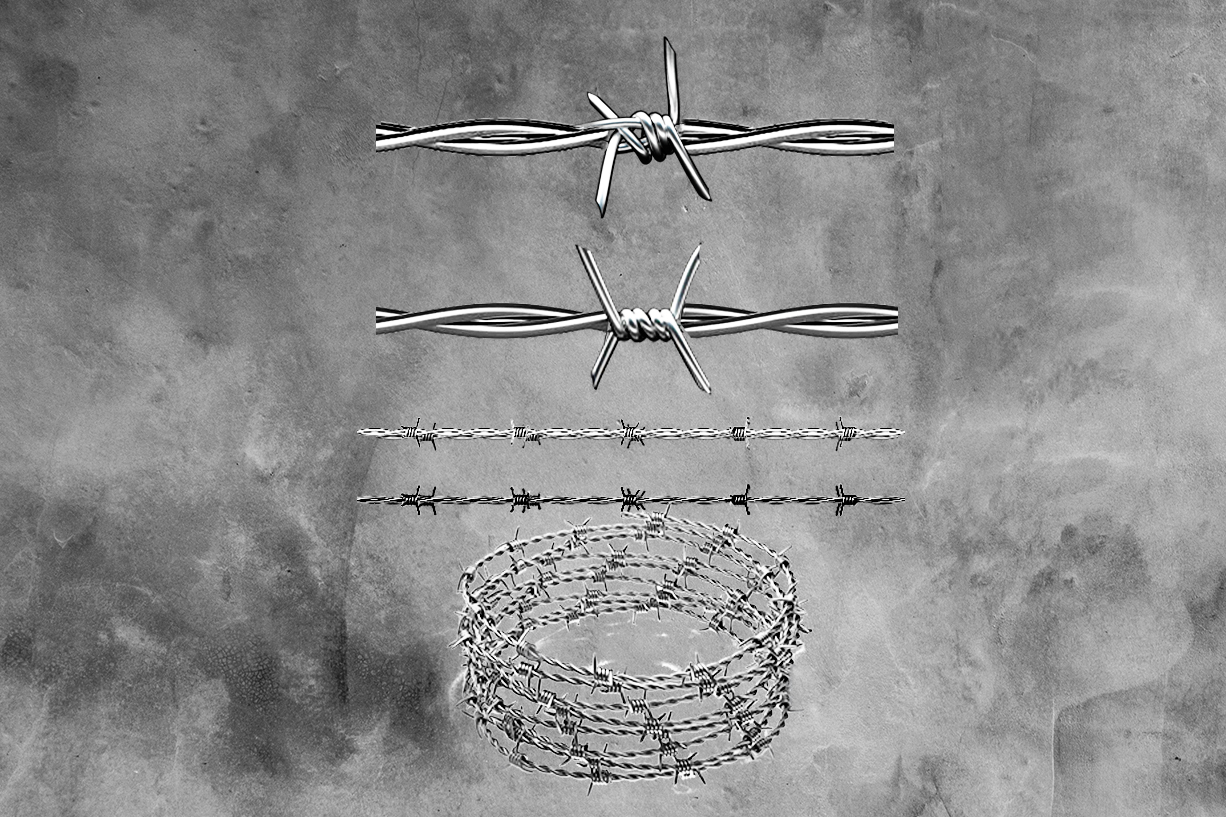

- Barbed Tape Wire

- Welding Wire Mesh

*For special specification requirements, please send us your inquiry.

Expanded metal mesh is a multi-purpose product. The metal plate such as iron, aluminum, stainless steel is slit and expanded at the same time with a JUNEN high-speed expanded metal machine to form a mesh in the shape of a diamond grid.

For extremely demanding projects, high-strength and high-toughness materials are used to create high-standard products which are perfect, forming a diamond shape, and perforated plate nets with the same size and shape rules.

The waste material will be generated during the expansion of the production process, saving a lot of material costs. Moreover, the expanded metal mesh sheet is lighter in weight and stronger in structure than the original sheet.

The Wire Conveyor Belt can be used in any kind of production line for transporting. The wire conveyor belt is from one place to another in production lines, transportation lines, oven lines, cooling and freezing lines, and is formed by weaving metal wires in various shapes.

Applications: Freezing food machinery, canned food machinery, sea food machinery, continuous baking machinery, heat treatment machinery, glass machinery, chemical machinery, general purpose conveyors, special conveyors, architecture application, interior design application.

The conveyor weave belt is preferred in many different sectors, in accordance with the specifications of machinery used. The advantage of the weave belt is the ability to manufacture conveyor belts in desired measurements, with desired materials and required specifications. While a separate material and weave type is used for weave belt production that would come to contact with high-temperature food, a weave belt to be used for chemical washing process can be manufactured with an entirely different technique.

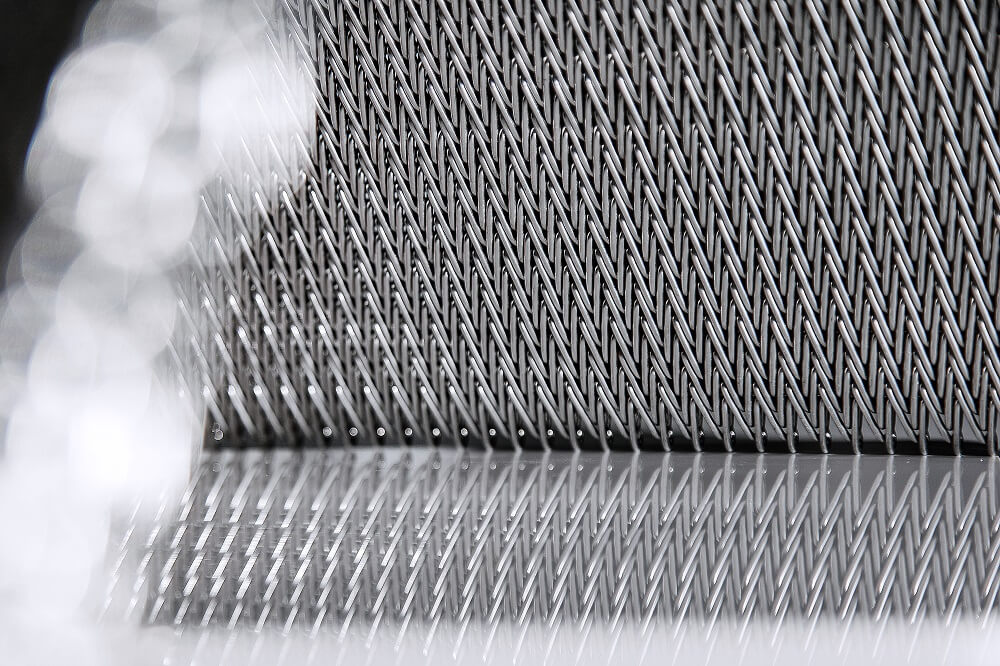

Mesh grid, also known as wire cloth or wire fabric, is a versatile metal mesh product that can be used effectively in countless applications globally. Popular uses for wire mesh include stainless steel wire mesh for filters, steel wire mesh for partitions, and PVC wire mesh for machine guards. From industrial to commercial applications, wire mesh is a common metal product that is used by many daily. It concludes the Plain weave mesh, crimped mesh, woven mesh and chain link fence mesh.

Perforated metal mesh is made of metal plate as raw material, using a special perforated mesh machine to punch into different shapes such as round, square, rectangular or quincunx. Perforated metal perforated mesh also adds structural integrity to stairwells, sidewalks or mezzanine structures, while providing an aesthetic appearance that complements multiple styles.

The diamond weave pattern of the JUNEN Chain Link Fence provides powerful, durable and flexible features, from light residential to heavy commercial fences, and all applications in between is one of the most popular practical fence choices. It is relatively easy to install, and it is very economical, beautiful and practical.

Razor barbed tape wire is a highly developed form of the traditional barbed wire.

It is a blocking device formed by the combination of sharp pointed steel sheets and high-tensile wire. It is the most common barrier material. Fence barriers with galvanized metal strips and galvanized core steel wires with sharp edges are designed to prevent vandals and unauthorized intruders from entering the site.

JUNEN barbed wire is an excellent blocking device. It is the most common blocking material, such as various types of fences, orchards, outdoor land, parking lots, public buildings or private houses, etc., designed to prevent vandals and unauthorized intruders from entering the site.

Welded mesh is made of cold-rolled steel in a horizontal and vertical arrangement, and its intersection is formed by electrical welding, which has high shear strength and strong impact resistance against construction load. Because its strength is higher than that of steel, it can reduce the amount of steel material and indirectly reduce its own weight. Because the quality can be controlled, it is manufactured on an automatic welding machine to ensure uniform welding wire spacing and consistent cross-sectional area.